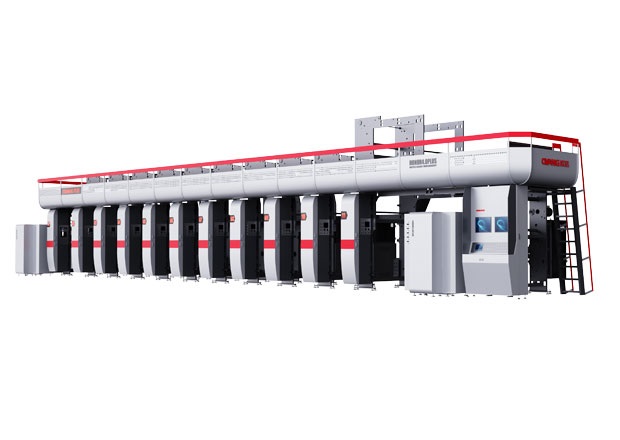

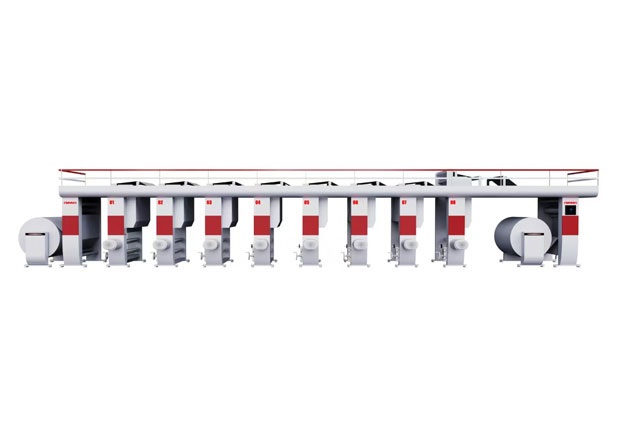

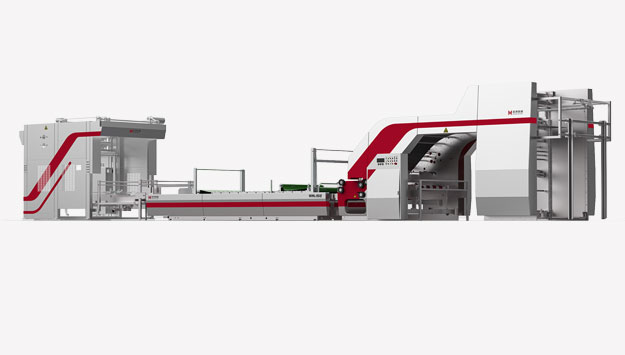

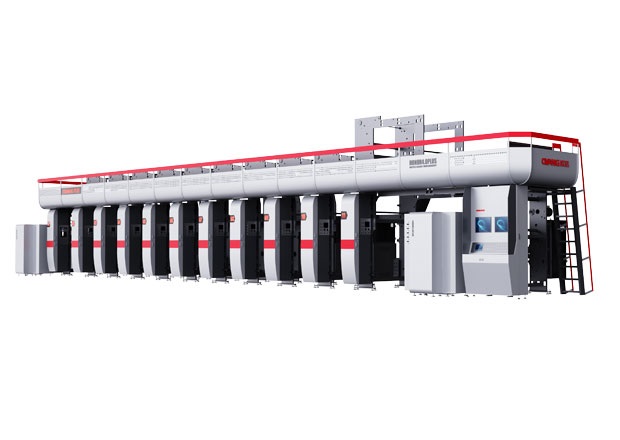

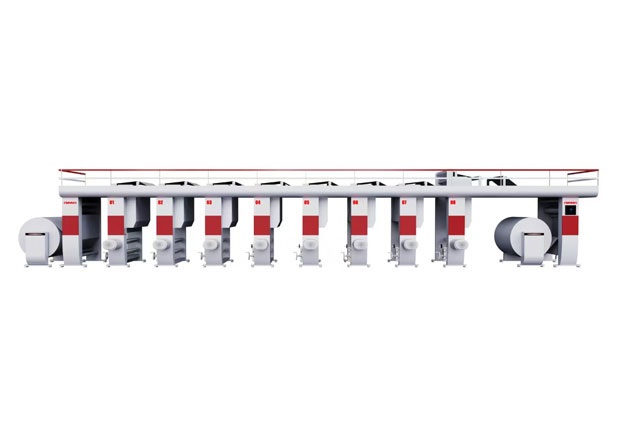

What Is a Rotogravure Printing Machine?

A rotogravure printing machine is an advanced piece of printing and coating equipment designed to achieve high-quality, precise, and durable printing results on flexible packaging materials. It combines the efficiency of rotogravure printing technology with the versatility of lamination processes, making it ideal for industries such as food packaging, pharmaceuticals, and consumer goods. In a rotogravure printing machine, the printing cylinder is engraved with microscopic cells that hold ink, transferring it directly onto materials like plastic films, aluminum foils, or paper. The lamination process then bonds multiple layers together, creating a strong, functional, and visually appealing final product. OUNUO's machines are designed with precision engineering and intelligent control systems to ensure consistent printing quality, smooth operation, and environmental sustainability throughout the entire production process.

How Does a Rotogravure Printing Machine Operate Step by Step?

The rotogravure printing machine operates through a detailed sequence that integrates printing and lamination into a seamless workflow. First, the substrate passes through the unwinding unit, where it is tensioned and aligned to ensure accurate registration. Next, the engraved cylinder applies ink uniformly using a doctor blade system, which removes excess ink to maintain clean and defined image areas. The inked design is then transferred to the substrate under precise pressure and temperature control. After printing, the material passes through a drying section that removes solvents and stabilizes the printed surface. The lamination stage follows, where adhesive is applied and the printed film is bonded to another layer, forming a laminated structure with improved durability, barrier protection, and aesthetic quality. Each stage of the rotogravure printing machine is automated for synchronization, ensuring accurate color matching, minimal waste, and excellent adhesion between layers.

What Makes the Rotogravure Printing Machine Ideal for Modern Packaging?

Modern packaging requires not only visual appeal but also functionality, sustainability, and durability—qualities that the rotogravure printing machine delivers efficiently. Its ability to print with exceptional clarity and consistency allows brands to achieve premium packaging aesthetics. Moreover, the lamination process enhances moisture resistance, heat sealing performance, and product protection, which are essential for food and pharmaceutical industries. OUNUO's machines are built with advanced tension control, energy-efficient drying systems, and environmentally friendly ink management, aligning with the company's commitment to sustainable innovation. By integrating printing and lamination in one continuous process, the rotogravure printing machine minimizes manual intervention and improves production efficiency, ensuring a smooth, precise, and eco-conscious manufacturing workflow that meets global quality standards.

How Does the Rotogravure Printing Machine Ensure Printing Precision?

Precision is at the core of every rotogravure printing machine operation. The engraved printing cylinder, typically made from copper-plated steel and coated with chrome, ensures uniform ink transfer across every print cycle. Sophisticated registration systems detect and adjust alignment errors in real time, maintaining exact color placement and image sharpness. Temperature and pressure controls during both printing and lamination guarantee optimal ink adhesion and layer bonding, preventing defects such as bubbles, wrinkles, or misalignment. Additionally, OUNUO's intelligent control interface enables operators to monitor and adjust parameters easily, achieving consistent results even during long production runs. This high level of precision and automation allows manufacturers to meet demanding industry requirements for high-speed, large-volume, and multi-layer packaging production.

Why Choose a Rotogravure Printing Machine for Your Production Line?

Choosing a rotogravure printing machine offers manufacturers a versatile and efficient solution for producing high-quality laminated packaging materials. It supports a wide range of substrates, including PET, BOPP, PE, aluminum foil, and paper, making it adaptable for various market applications. The integration of printing and lamination processes reduces handling time and improves productivity, while automated control systems enhance consistency and minimize material waste. OUNUO's commitment to eco-innovation ensures that its rotogravure printing machines are designed with sustainability in mind, incorporating energy-saving drying systems and low-emission ink technology. By utilizing this advanced equipment, manufacturers can achieve superior print clarity, long-lasting lamination strength, and environmentally responsible production—all essential for meeting the growing demands of the global flexible packaging market.

English

English