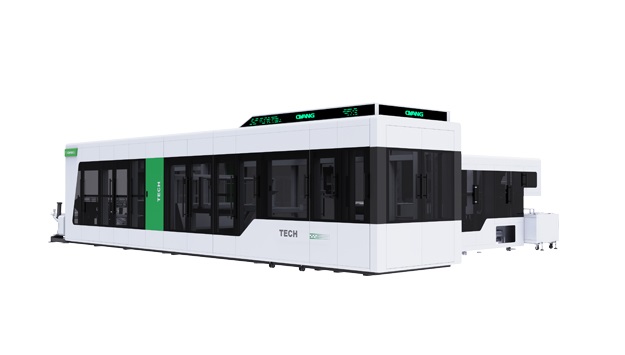

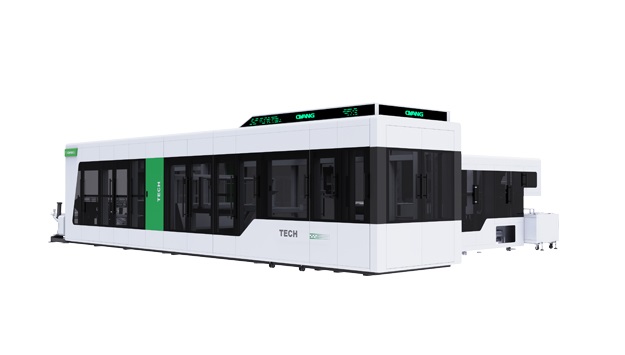

What Is a Non-Woven Bag Making Machine?

A non-woven bag making machine is a modern manufacturing solution designed to produce eco-friendly, reusable bags from non-woven fabric materials. Unlike traditional plastic bag production, this technology relies on synthetic fibers that are bonded together through heat and pressure, creating a strong, breathable, and biodegradable alternative to plastic. The machine automates every stage of production—from feeding raw fabric to printing, cutting, folding, and sealing—ensuring consistent quality and precision in every finished bag. By combining advanced mechanical systems with intelligent control panels, the non-woven bag making machine offers high-speed, stable performance while supporting sustainability goals. This automated process reduces human error, improves production efficiency, and supports the global shift toward green packaging solutions.

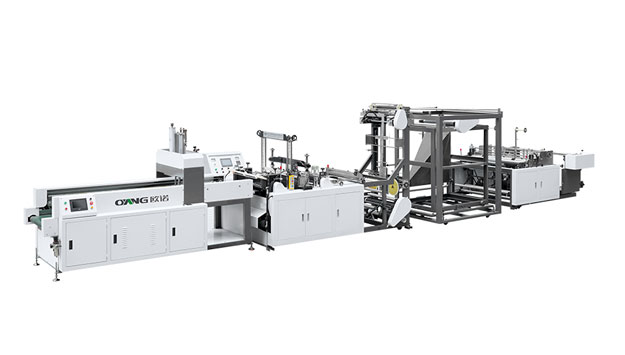

Advantages of Using a Non-Woven Bag Making Machine in Eco Packaging

The non-woven bag making machine has become essential in the eco packaging industry because it enables large-scale production of durable, environmentally responsible bags. These bags are not only reusable and recyclable but also offer impressive printing adaptability, allowing for creative and attractive designs that enhance brand visibility. The machine's integration of ultrasonic sealing technology ensures strong seams without the need for adhesives, making it cleaner and more sustainable. Its automated temperature and tension control systems help maintain consistent material quality, even under long production runs. Through these technological advantages, the non-woven bag making machine contributes to the global reduction of plastic waste while enabling manufacturers to produce packaging that meets modern ecological and aesthetic standards.

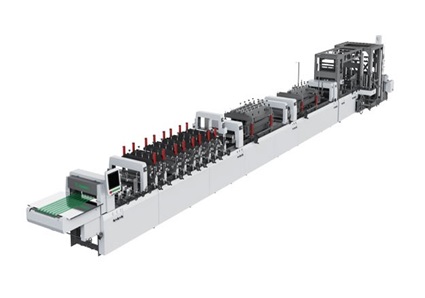

How Does the Non-Woven Bag Making Machine Support Sustainable Manufacturing?

Sustainability is at the core of the non-woven bag making machine's development. The machine allows manufacturers to use recyclable non-woven fabrics that decompose naturally over time, unlike plastics that linger in the environment for decades. Moreover, the production process consumes less energy and emits fewer pollutants due to the absence of chemical adhesives or harmful coatings. By incorporating programmable control systems, operators can precisely manage material consumption and waste output, further enhancing eco-efficiency. The widespread adoption of the non-woven bag making machine represents a shift in global manufacturing practices toward greener, circular economies where packaging serves both functional and environmental purposes.

What Makes the Non-Woven Bag Making Machine Ideal for Modern Businesses?

The non-woven bag making machine caters perfectly to modern businesses seeking reliable and sustainable packaging solutions. Its versatility allows for the creation of a wide range of bag types—shopping bags, gift bags, promotional bags, and more—all customizable to fit branding needs. The flexibility in size, shape, and design ensures compatibility with various industries, including retail, food service, and healthcare. With intelligent automation, digital touch-screen interfaces, and precision servo controls, the machine minimizes downtime while maximizing output quality. For brands prioritizing eco-conscious identity, the non-woven bag making machine offers an innovative, future-ready solution that aligns with environmental commitments and consumer expectations for sustainability.

Future Trends and Technological Innovation in Non-Woven Paper Bag Production

The non-woven bag making machine continues to evolve alongside global sustainability initiatives and digital manufacturing trends. Innovations such as real-time monitoring, energy optimization systems, and smart sensor integration are redefining efficiency and reliability in bag production. As environmental regulations tighten and consumers increasingly favor sustainable alternatives, manufacturers are investing in more intelligent, energy-efficient machinery. The continuous improvement in non-woven fabric quality and customization capabilities ensures that this technology remains at the forefront of eco-packaging innovation. The non-woven bag making machine not only meets the current demand for reusable bags but also paves the way for the next generation of sustainable production solutions that blend performance, creativity, and responsibility.

English

English