en

-

Machine

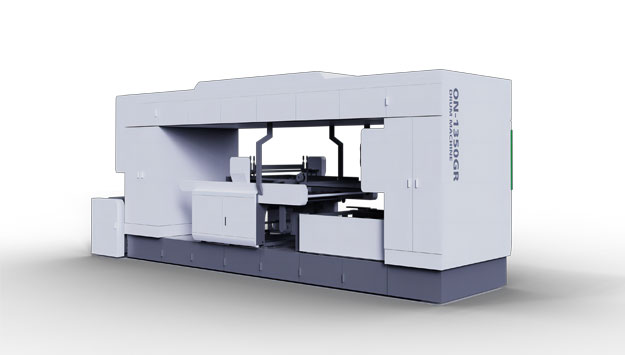

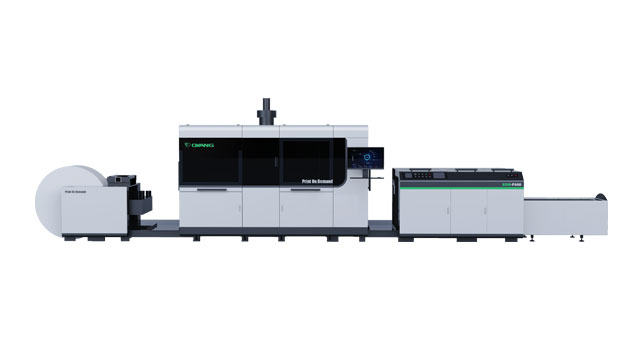

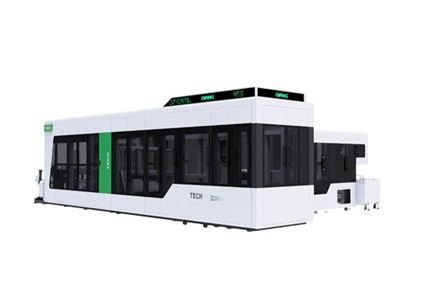

Paper Bag Making MachineSOS Paper Bag Making Machine Paper Bag Making Machine With Twisted Handle Paper Bag Making Machine With Flat Handle Satchel Paper Bag Making Machine Paper Bag With Handle Making Machine Roll Feed Paper Bag Making Machine Sheet Feed Paper Bag Making Machine Luxury Paper Bag Making Machine Food Paper Bag Making Machine Eco Paper Bag Making Machine

- About Us

- Industries We Serve

- Inspirations

- Resources

- Services

- Contact

English

English